Omsi - 60 years of quality

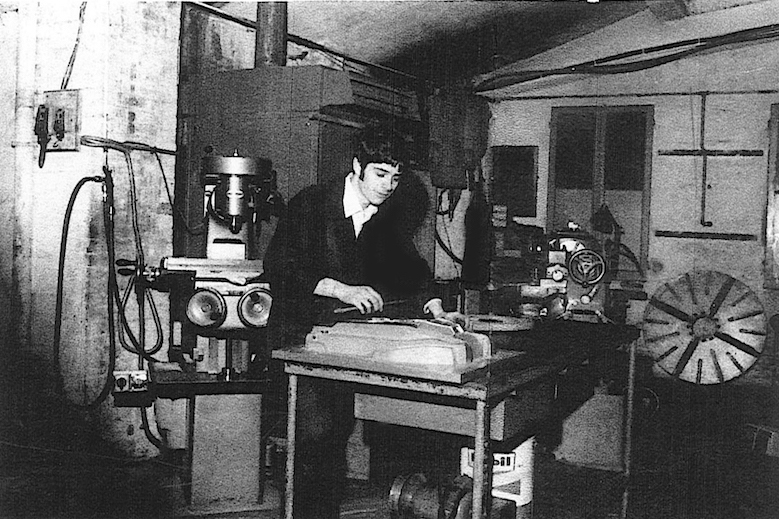

OMSI (Officina Meccanica Stampi Industriali)

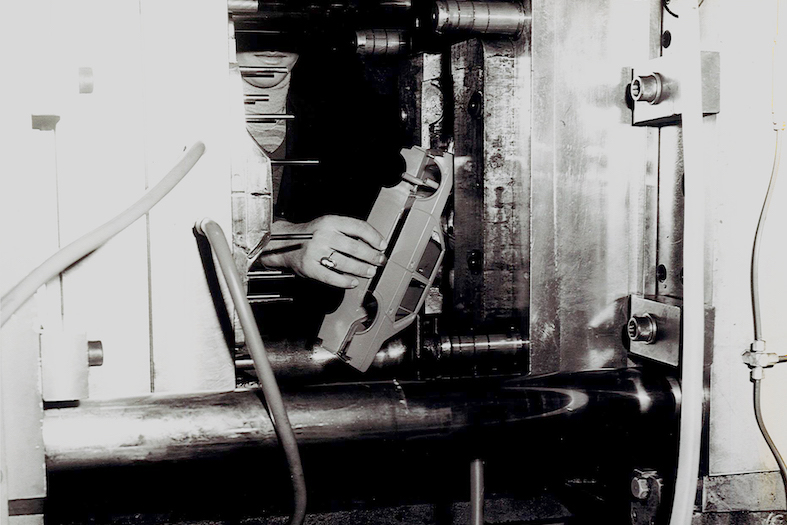

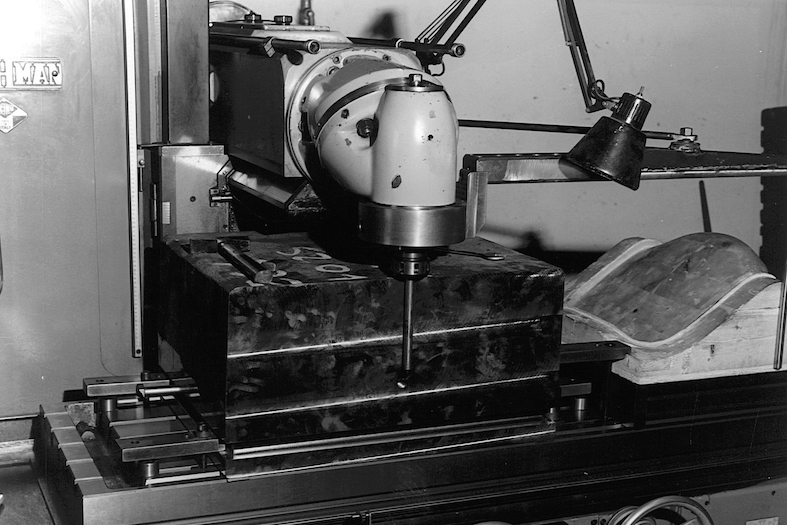

Once the company expanded its production to include plastic seating for school, community and public facilities, OMSI quickly became an established international benchmark thanks to the use of state-of-the-art technology, a wide availability of moulds for different types of products and a selection of the most suitable plastic materials used.

OMSI offers its customers a complete and customised service from the design and production of all components to the installation of the seats and after-sales service, providing a product of excellence that is safe, durable and eco-friendly.

Omsi's turnover has been growing steadily since 2004, even doubling in the last two years, and for the 80% it is achieved in foreign markets.

Today, looking back, we have no doubts about what lies ahead. For we have long since begun our journey with an eye on tomorrow.